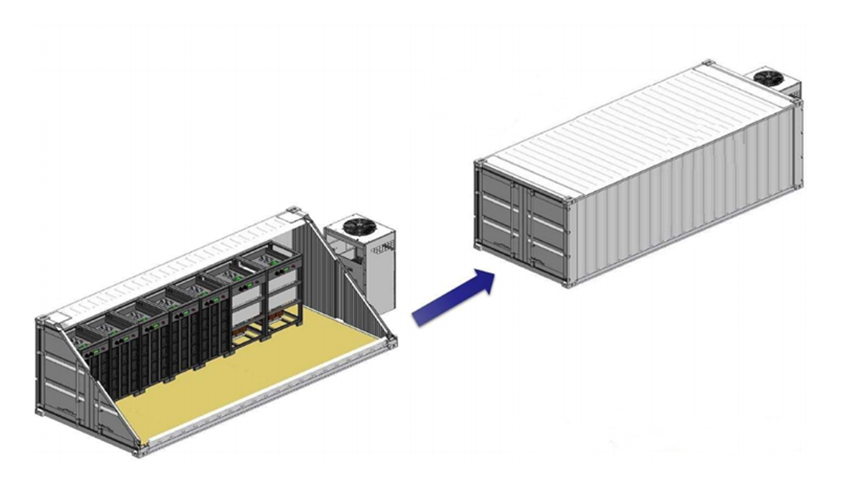

The container energy storage system has the advantages of short construction time, convenient movement, and a small footprint. In recent years, it has been continuously applied in various large-scale projects. As an upgraded version of the internal cooling mode of the battery container, the prefabricated cabin is gradually becoming a mainstream form.

The commonly used thermal management solutions for energy storage battery prefabricated cabins mostly use air conditioners as radiating components. Through the synergistic effect of compressors and refrigerants, the temperature inside the cabin can be controlled to be lower than the external ambient temperature, and a temperature deficit between the interior and exterior can be achieved. At the same time, through the optimization of the arrangement position of the air conditioner, combined with a certain air supply duct structure, the thermal management efficiency of the air conditioner to the battery cluster can be improved as much as possible.

Take 2MWh ESS with 0.5C charge&discharge battery as an example. The system uses a prefabricated cabin as the battery carrier, the size of the cabin is comparable to a 40-foot container, and the length is 12 meters. Batteries are arranged in clusters on both sides of the long wall of the cabin. The battery compartment is equipped with 2 or 4 cabinet-type industrial air conditioners according to the needs, and the air conditioners are arranged between the battery clusters. According to different thermal management modes, the air in and out of the air conditioner can be divided into three types: front air inlet and top air outlet, front air inlet and rear air outlet, and front air inlet and bottom air outlet.

The first type of front inlet and top outlet is the most commonly used mode. The hot air enters from the air inlet below the front of the air conditioner and is cooled by the condenser, and the cold air is discharged from the top air outlet.

The second mode of air intake at the front and air outlet at the rear is to directly leave a certain distance (50~100mm) between the rear of the air conditioner and the bulkhead. The hot air enters from the front and the cold air is discharged from the rear air outlet.

The third mode of front air intake and the bottom air outlet is to send cold air from below the air conditioner and send the cold air to the bottom of each battery cluster through the air duct under the floor. A certain pressure is created by the fan to make the cold air flow from bottom to top in the battery cluster. The three air supply methods of air conditioners have their advantages and disadvantages. The main contradiction is that it is difficult to take into account the heat dissipation efficiency and the temperature balance between different battery modules.